DRATEC Hot Box Core Shooting Machine, also named hot box core shooter, is a moulding equipment widely used in the foundry casting industry. High production efficiency, accurate size, smooth appearance, better sand core strength and hardness, and the ability to produce castings with complicated internal cavities. It’s suitable for casting small and medium-sized casting cores such as automobiles, valves, and machine tools. It is ideal for casting enterprises to improve product quality and production efficiency. Both the vertical parting and horizontal parting can be used

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

| Model | ZH860R-30S | ZH1080R-40S | ZH1210R-50S | ZH1412R-60S | ZH1814R-80S | ZH2215R-150S | ZH3020R-300S |

|---|---|---|---|---|---|---|---|

| Maximum core box size (mm) | 800×600 | 1000×800 | 1200×1000 | 1400×1200 | 1800×1400 | 2200×1500 | 3000×2000 |

| Opening / closing distance (mm) | 350–850 | 350–850 | 400–900 | 450–950 | 500–1000 | 500–1000 | 500–1000 |

| Maximum sand shot amount (kg) | 30 | 40 | 50 | 70 (Customizable) | 100 (Customizable) | 150 (Customizable) | 500 (Customizable) |

| Single station cycle time (s) | 20 / 30 | 25 / 30 | 30 | 35 | 40 | 40 | 60 |

| Number of molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds |

| Drive mode | Servo | Servo | Servo | Servo Hydraulics | Servo Hydraulics / Frequency | Servo Hydraulics / Frequency | Servo Hydraulics / Frequency |

| Hydraulics | Hydraulics | Hydraulics | Conversion motor | Conversion motor | Conversion motor | ||

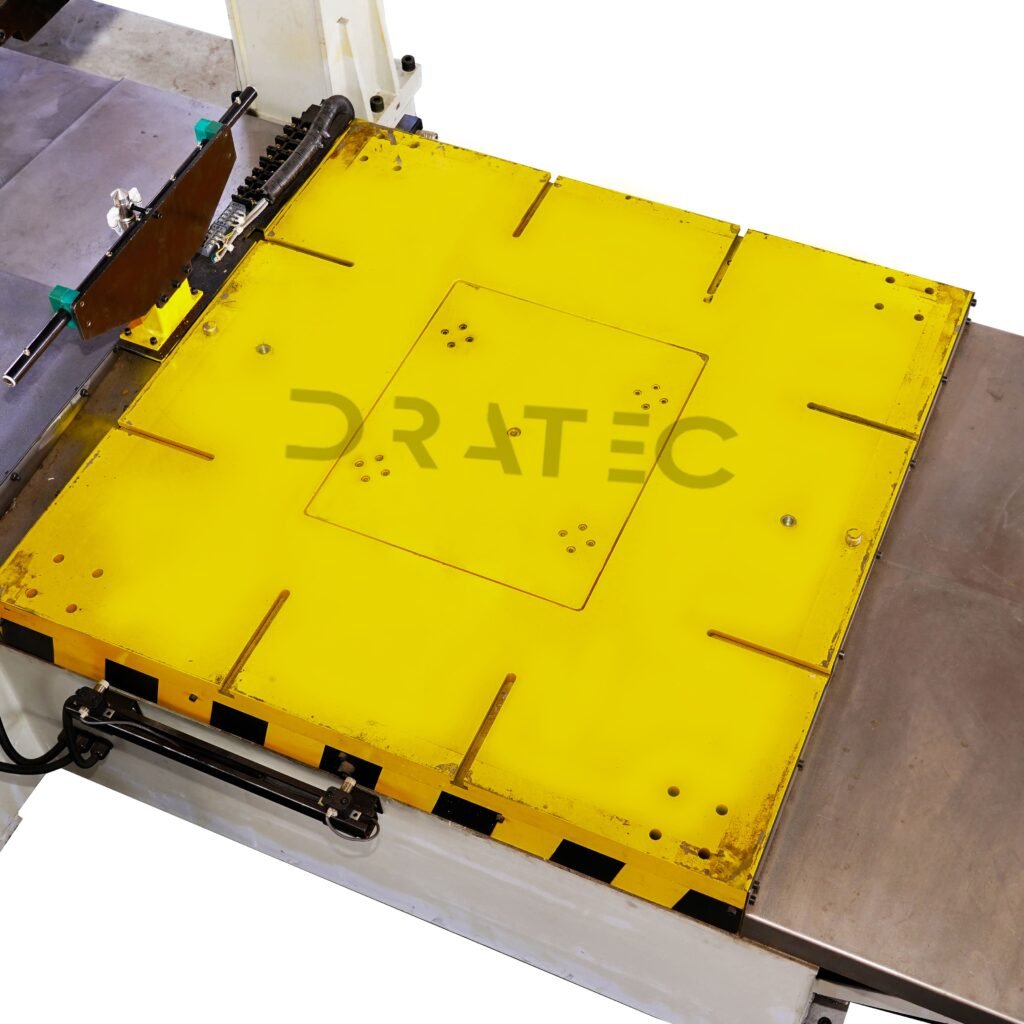

| Coring method | Workbench removal | Workbench removal | Workbench removal | Workbench removal | Workbench removal | Workbench removal | Workbench removal |

Features PLC program control with an LCD interface for parameter setting, process monitoring, and fault diagnosis. Supports manual, automatic, and jog control modes with digital temperature display and regulation.

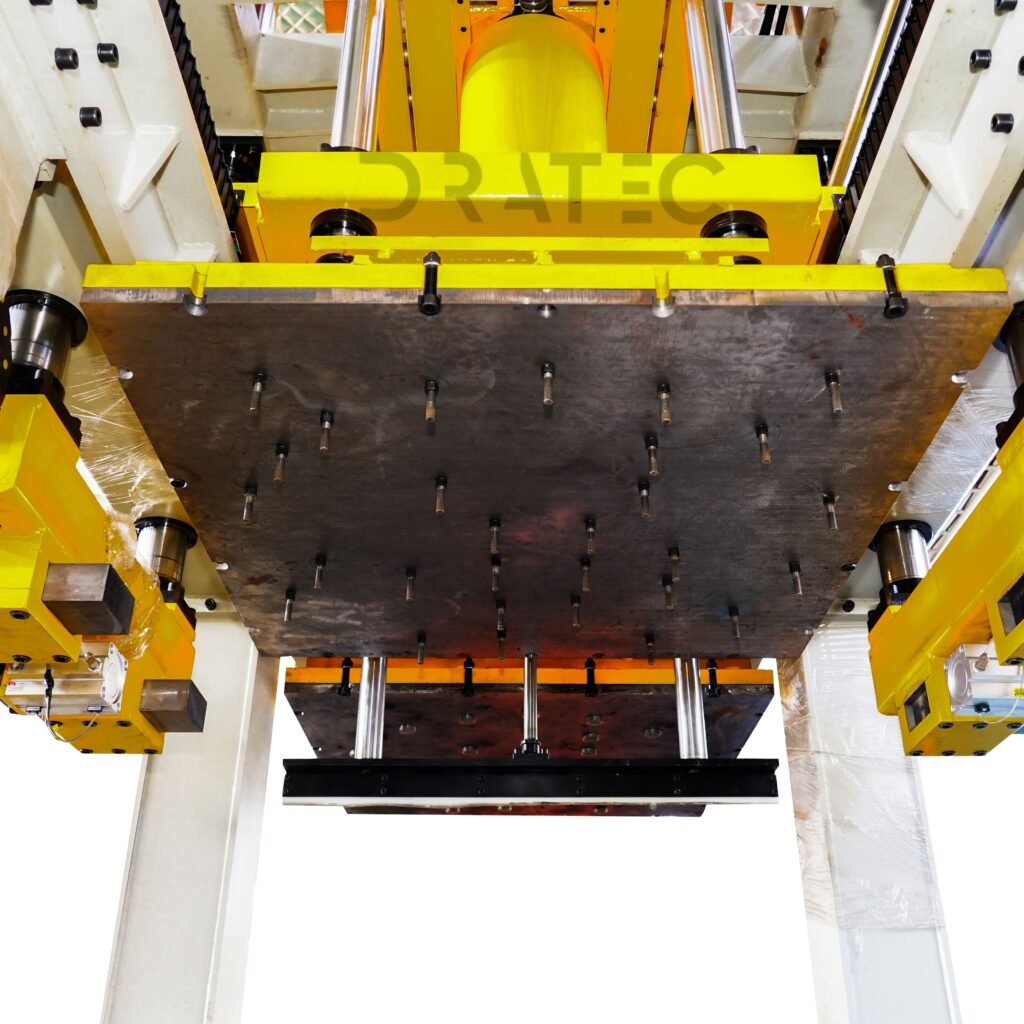

Automatic sand filling and cleaning of the shooting head after each cycle, without water cooling. Alarm prompt for mold opening, with a middle slide mechanism for core removal. The mold template utilizes high-frequency hardened and hard-chrome-plated guide rails for high clamping precision and extended service life. Supports multi-directional core extraction.

Optional components enable fast, impact-free movement, prolonging service life. Electromagnetic overflow air-cooled hydraulic station reduces oil temperature and delays component fatigue. Post-mold opening, the template can rotate 90° for automated core pickup and removal

Vertical design with 2 to 6 mold opening modes. Some series offers a dual-mode opening and dual-station setup for simultaneous production of two molds. Drive modes: pneumatic, hydraulic, or combined pneumatic-hydraulic. Optional accessories: pattern plates, sandblasting quick-change plate devices, and sand feeding systems.