- support@domain.tld

- +86051983732179

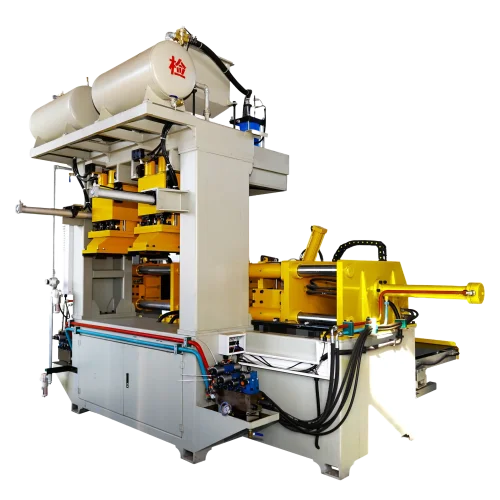

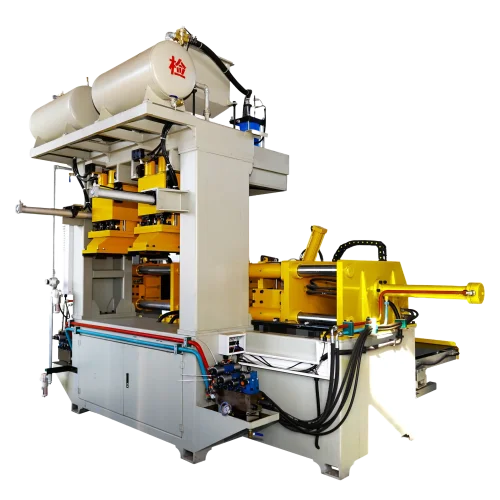

DRATEC Hot Box Core Shooting Machine, also named hot box core shooter, is a moulding equipment

widely used in the foundry casting industry. High production efficiency, accurate size, smooth

appearance, better sand core strength and hardness, and the ability to produce castings with

complicated internal cavities. It’s suitable for casting small and medium-sized casting cores such as

automobiles, valves, and machine tools. It is ideal for casting enterprises to improve product quality and

production efficiency. Both the vertical parting and horizontal parting can be used

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

| Model | Z9405R-15S | Z9406R-20S | Z9407R-30S | Z9408R-40S | Z9409R-60S | Z9410R-80S |

|---|---|---|---|---|---|---|

| Maximum core box size (mm) | 500×400×420 | 600×500×420 | 700×500×450 | 800×600×450 | 900×650×450 | 1000×800×500 |

| Opening/closing distance (mm) | 300–800 | 400–900 | 450–950 | 450–950 | 450–950 | 500–1000 |

| Maximum sand shot amount (kg) | 15 | 30 | 50 | 50 | 80 | 100 |

| Single station cycle time (s) | 25 | 25 | 30 | 30 | 35 | 35 |

| Drive mode | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Coring method | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal |

This machine is designed for fully automatic production of shell cores and shell molds using phenolic

resin-coated sand, specifically for vertical parting applications. It ensures high efficiency, excellent gas

evolution control, and significant material savings.

Ideal for vertical parting molds, it produces shell cores and molds with high

efficiency, reduced gas emissions, and optimal sand usage.

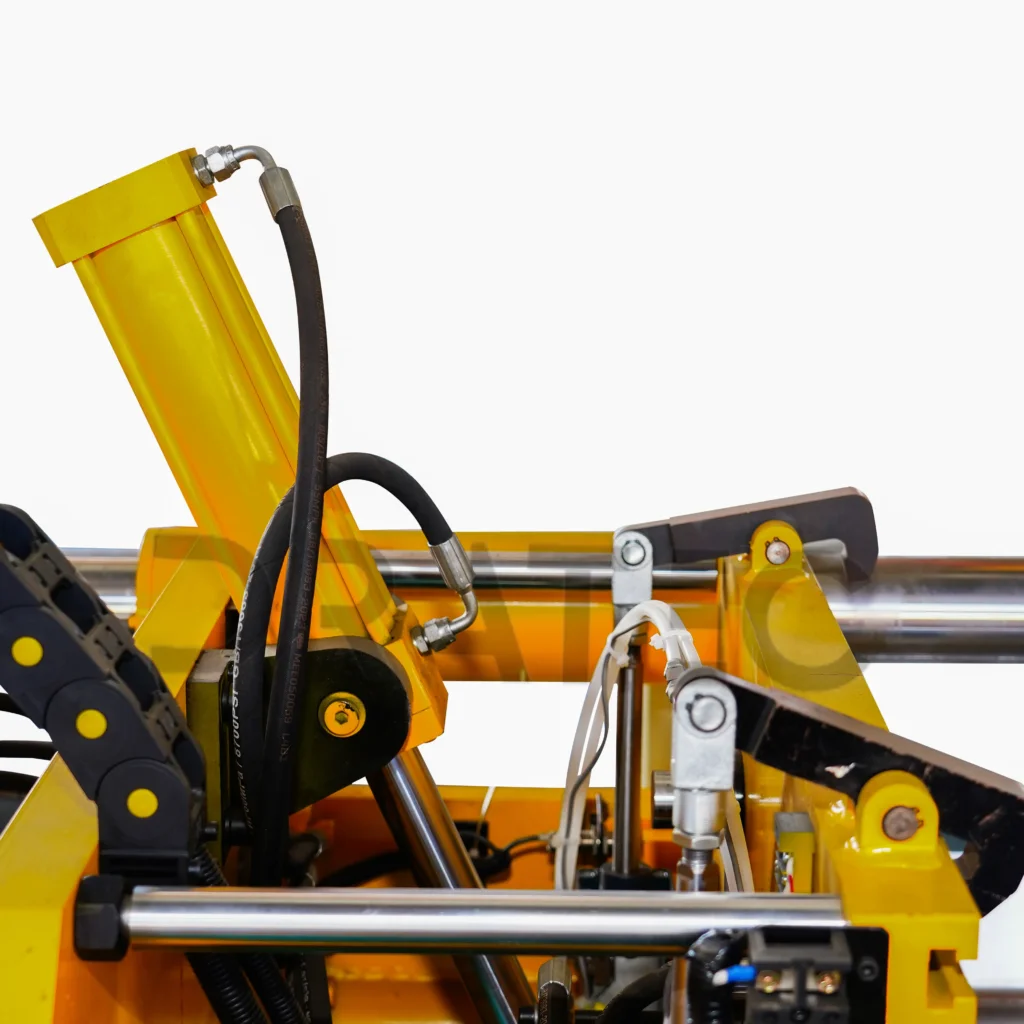

Equipped with PLC program control and a touchscreen interface for parameter

setting, real-time monitoring, and fault diagnosis. Supports manual, automatic, and jog operations

with digital temperature control.

Features mid-to-high frequency hardened guide rails for enhanced

wear resistance, and a hydraulic drive system for stable, vibration-free movement. Rotating slip-ring

pipelines prevent hose tangling.

Offers multiple program settings to flexibly produce shell cores or molds.

Automatic sand scraping after shooting minimizes waste and lowers labor requirements.

Produces sand cores with uniform wall thickness and virtually zero excess sand waste

The dual-station model allows simultaneous or alternating production of

two molds. Independent program settings ensure non-interference between stations.

Enables parallel processing of two molds, further boosting production

capacity

DRATEC professional team to provide comprehensive installation, debugging and after-sale services in Brazil. Their local knowledge and expertise ensure the successful completion of your installation, giving you complete peace of mind