- support@domain.tld

- +86051983732179

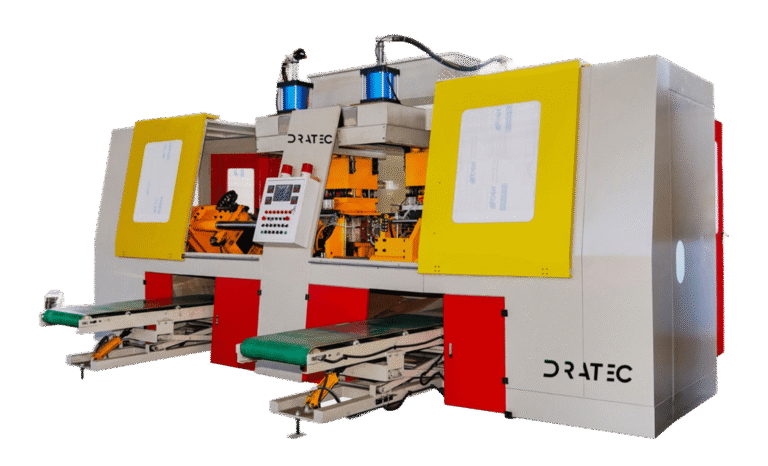

DRATEC Fully Automatic Shell Core Shooting Machine, also called Shell Core Making Machine ,Sand Core Shooter Machine, Shel Moulding Machines…, Fu ly automatic removal is suitable for vertical parting molds. It produces she l cores and she l molds by heating phenolic resin coated sand. It has high production efficiency, saves sand, and has less sand core gassing, widely used in foundries and metal workshops

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

| Model | Z955SG-15D | Z956SG-20D | Z957SG-30D | Z958SG-40D | Z987SG-60D | Z1090SG-80D | Z1090SG-80D (Single station) |

|---|---|---|---|---|---|---|---|

| Maximum core box size (mm) | 500×400×420 | 600×500×420 | 700×500×450 | 800×600×450 | 800×700×450 | 1000×800×500 | 1000×800×500 |

| Mold closing distance (mm) | 300–800 | 400–900 | 450–950 | 450–950 | 450–950 | 500–1000 | 500–1000 |

| Maximum sand shot amount (kg) | 15 | 30 | 50 | 50 | 80 | 100 | 100 |

| Single station cycle time s | 25 | 28 | 30 | 35 | 38 | 45 | 45 |

| Drive mode | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Coring method | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal | Conveyor belt removal |

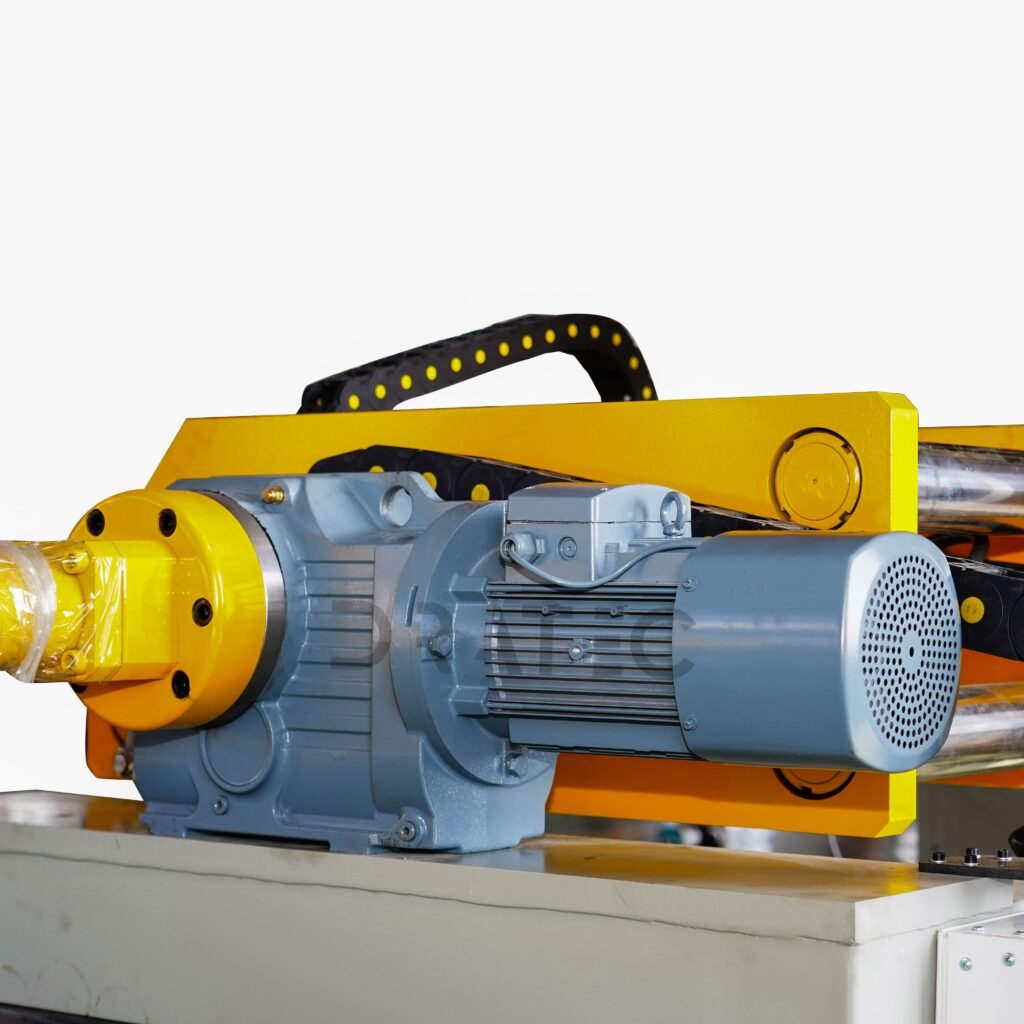

| Flip method | Motor + reducer | Motor + reducer | Motor + reducer | Motor + reducer | Motor + reducer | Motor + reducer | Motor + reducer |

Fully automatic removal is suitable for vertical parting molds. It produces shell cores and shell molds

by heating phenolic resin coated sand. It has high production efficiency, saves sand, and has less sand

core gassing.

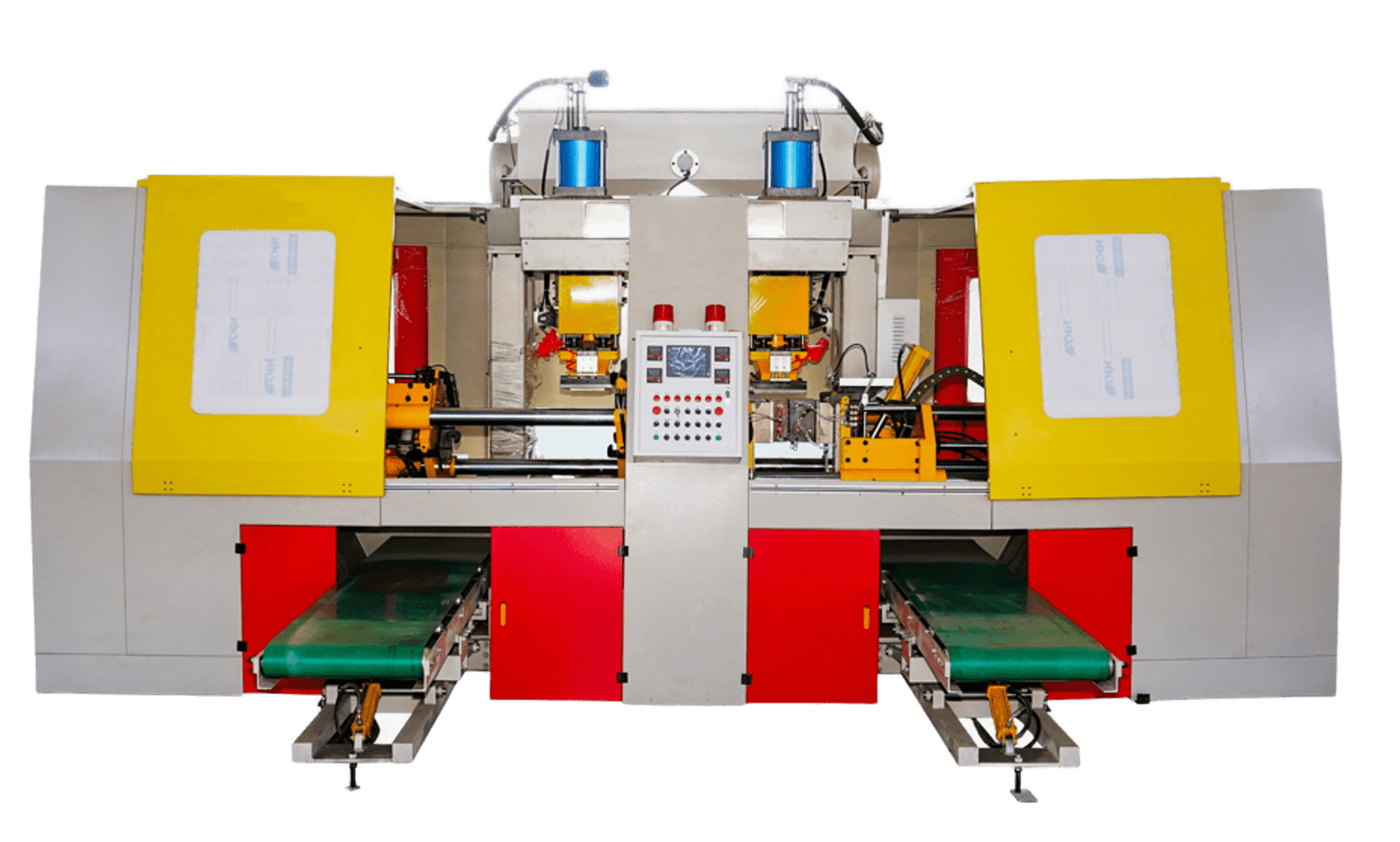

PLC program control, touch screen parameter setting, workflow display, fault diagnosis, manual/automatic/jog control, automatic digital display temperature control.

Featuring high wear resistance and long service life. Hydraulic drive ensures smooth operation without impacts or vibrations. The pipelines are connected by rotating slip rings to prevent entanglement.

It can produce shell cores and shell molds separately. It has an automatic function to scrape off the excess sand after sand shooting, which can reduce the waste of excess sand and lower the labor intensity

After sand shooting and shell formation, the template rotates 180° vertically to pour out the sand, and then swings ±35° for inclined vibration or air- blowing to pour out the sand, resulting in a uniform wall thickness of the sand core and no waste of excess sand.

The double-station model can complete the production of two molds simultaneously or alternately.

Two sets of programs can be freely set without interference. The double- opening model can

complete the production of two molds at the same time.

DRATEC professional team to provide comprehensive installation, debugging and after-sale services in Brazil. Their local knowledge and expertise ensure the successful completion of your installation, giving you complete peace of mind.