- support@domain.tld

- +86051983732179

DRATEC offers gravity die casting machine and tilting gravity die casting machine,both are the

solution for complicated automobile components. Gravity die casting Technology is ideal for diverse,

complex aluminium castings and is used in the production of automotive parts such as brake callipers,

knuckles, engine cylinder heads, suspension components, engine blocks, and pistons.

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

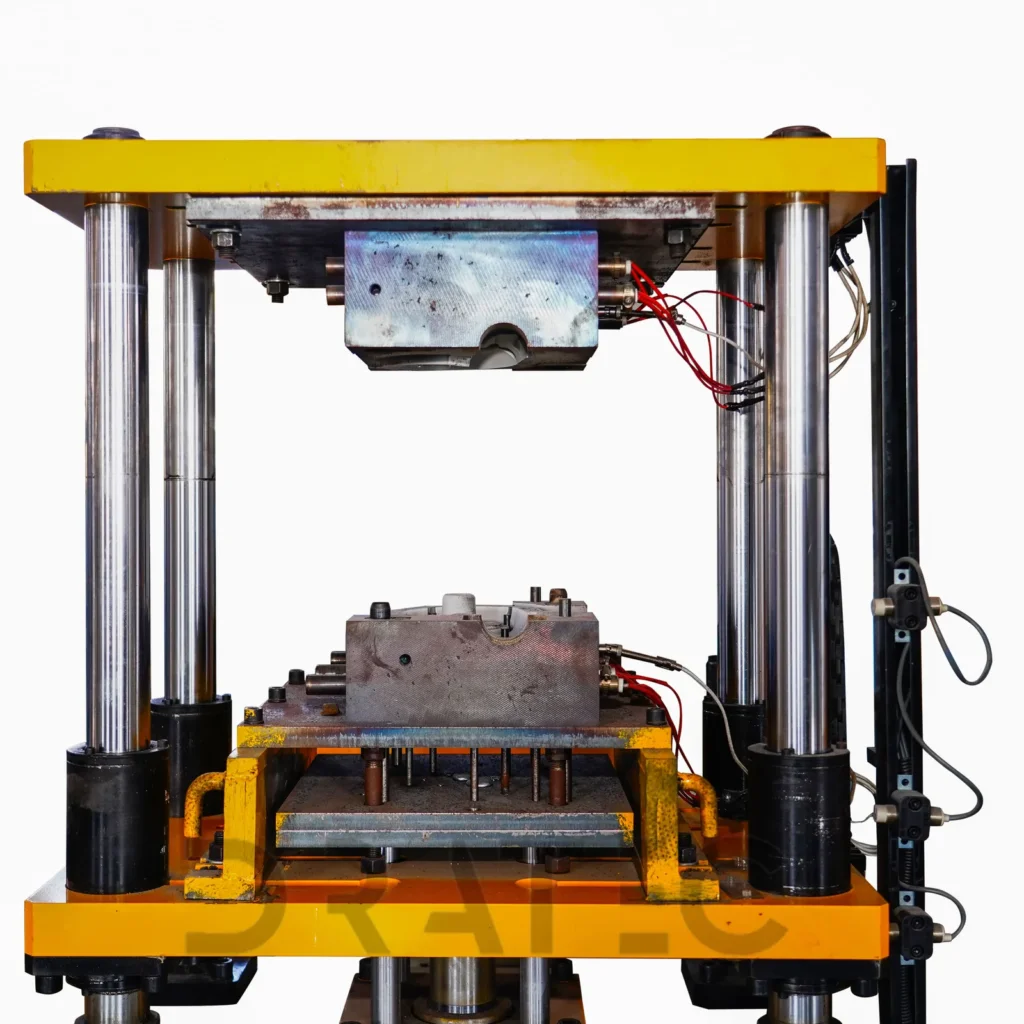

Gravity casting is a time-honored process that continues to hold significant potential for innovation. Addressing the need for versatility in customer foundries, Dratec has developed a modular machine concept designed for exceptional flexibility. This system enables quick changeovers for diverse casting applications and can be seamlessly scaled from basic to highly complex production. By integrating core pulls and additional clamping units, the base machine is perfectly equipped to manufacture even the most intricate castings with ease.

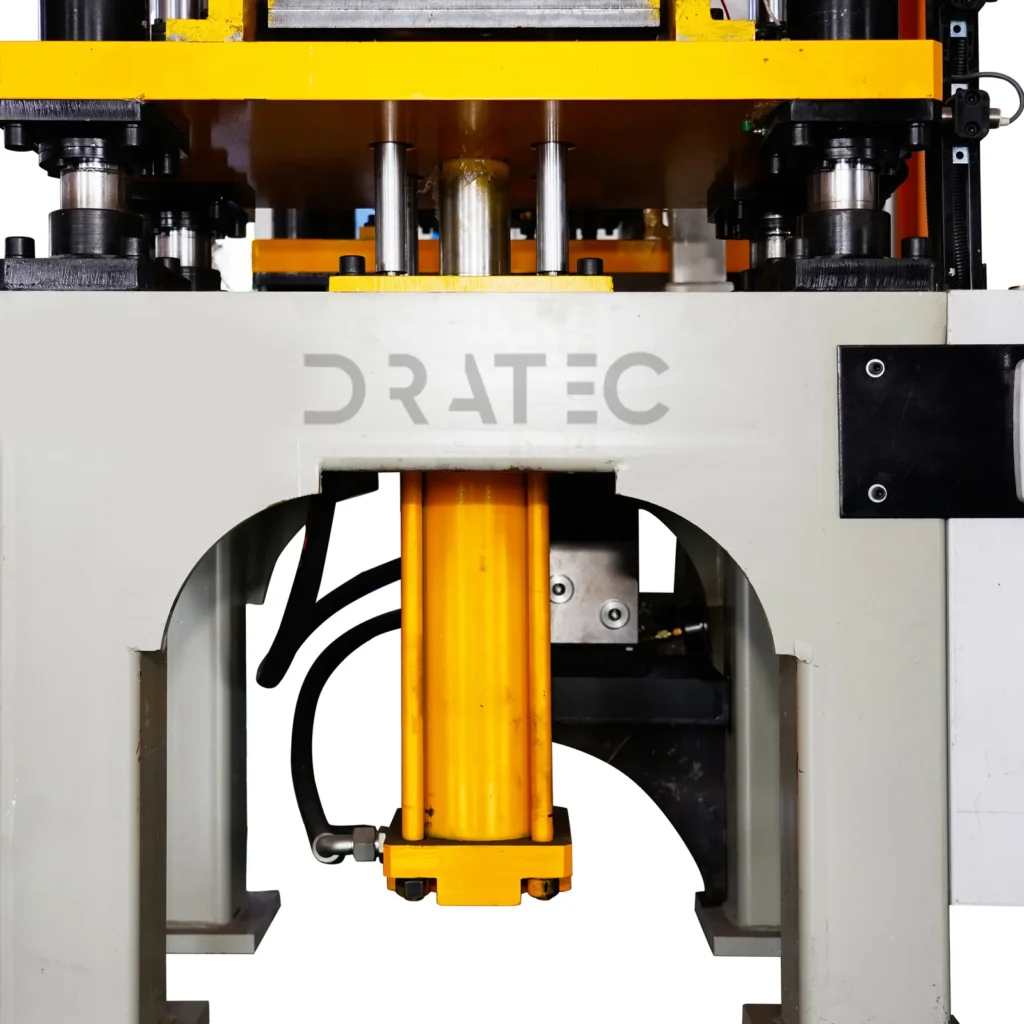

Compared with gravity casting, tilt casting offers the advantage of a significant reduction in the amount of recirculating material. This is achieved by utilizing the moulded part contour as a cast-in system and a reduced gating area. At the end of the filling process, the metal cast last collects in the gating area, which now serves as a feeder. The advantage of the modular design is also here the flexible attachment of core pulls with programmable travel speeds to adapt the machine to a wide range of requirements. The machines are completed by Dratec with external units for melt handling and part removal to form automatic casting cells.

Features PLC-based control with an intuitive LCD interface for parameter setting, real-time process monitoring, and automated fault diagnosis.

The mold can be rotated automatically or manually using the equipment’s turning mechanism, leveraging molten metal’s self-weight for filling—no external pressure required. This ensures smooth mold filling, minimizes defects like porosity and slag inclusions, and facilitates easy demolding and cleaning, thereby enhancing production efficiency.

Gravity pouring minimizes turbulence, resulting in castings with dense internal structure, superior surface finish, and high dimensional accuracy. Suitable for a variety of metals including cast aluminum, aluminum alloys, and copper alloys.

Equipped with high-frequency hardened, chrome-plated guide rails and an automatic lubrication system for all moving parts, reducing manual upkeep and extending equipment service life

Simple structural design enables easy operation and maintenance, making it ideal for small to medium-sized casting applications

Pouring parameters and molds can be customized to meet diverse casting requirements. The system offers broad process adaptability, low energy consumption, and high metal utilization, effectively reducing material waste.

Primarily designed with a four-pillar through-type or open-type mold parting structure. Optional

functions include multi-directional side core-pulling and upper/lower core ejection