- support@domain.tld

- +86051983732179

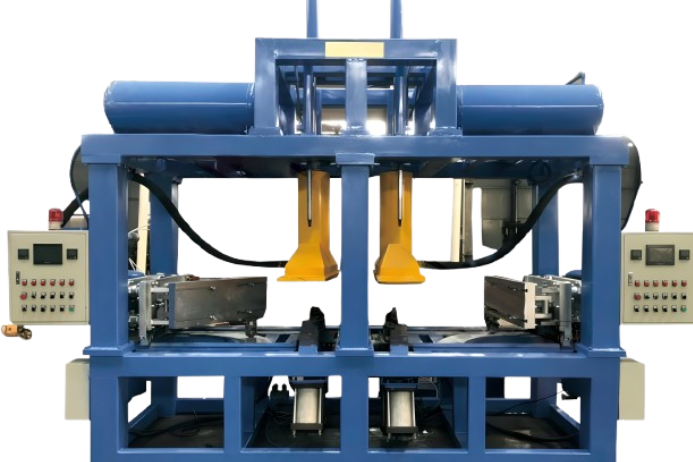

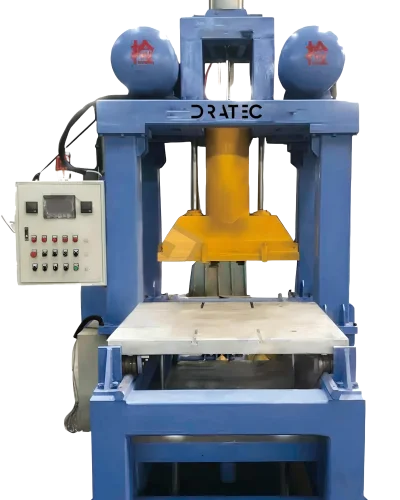

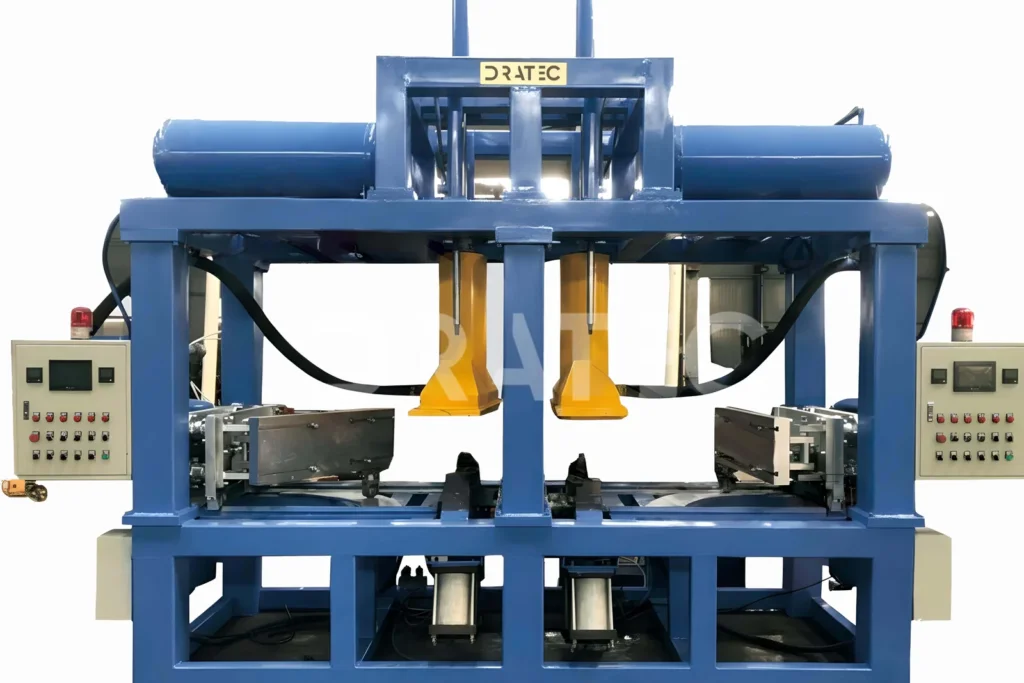

DRATEC Sand Lining Machine for Iron Molds, designed specifically for cast iron/cast steel parts,

improves surface finish to over Ra12.5μm and reduces scrap rate by more than 30%.

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

The rigid iron mold ensures the sand lining is formed

with extreme precision for every casting.

The fine, resin-coated sand produces very smooth casting surfaces,

reducing or eliminating the need for finishing work.

The sand lining insulates the molten metal, allowing it to cool more evenly and preventing defects like hard spots, shrinkage, and cracks, which are common when pouring iron or steel directly into a metal mold.

The lining prevents direct contact between the molten metal and the

expensive iron mold, drastically extending the mold’s lifespan

The process is highly automated, making it suitable for mass

production of consistent, high-quality castings like brake discs, hubs, and engine components