- support@domain.tld

- +86051983732179

DRATEC Tilting Gravity Die casting machine are the solution for complicated automobile components.

These machines are designed and manufactured in such a way that they can work efficiently. Our

machines are flexible and fully automated. We customise the machines according to customer

requirements

It can be used in conjunction with DRATEC machines and can also provide the following data:

1. Connection size between generator and equipment

2. What is the sand injection volume of the equipment in liters

3. It is preferable to provide equipment images and internal images of existing generators

| Model Name | Hi-end Configuration Generator | Conventional Style Generator |

|---|---|---|

| Model | DR-30H | DR-30C |

| Hourly Power Consumption | 2.5–3 kWh | 8–10 kWh |

| Working Theory | Heating based on aerodynamic principles, the compressed air blown out maintains a constant temperature of 80 ℃. The optimal evaporation temperature for amine water is at 80 ℃, resulting in low amine usage and fast curing time. | Heated by a heating rod, the temperature inside the compressed air tank blown out can reach up to 80 ℃, while the temperature of the newly replenished air cannot reach 80 ℃. The volatilization of amine water is not good, resulting in a large amount of amine used and a long solidification time for the sand core. |

| Characteristic | Independent PLC control, touch screen process parameter settings, workflow display, and fault diagnosis displays independently. | When two functions are shared with a device, parameter setting and switching can easily lead to mis-operation. |

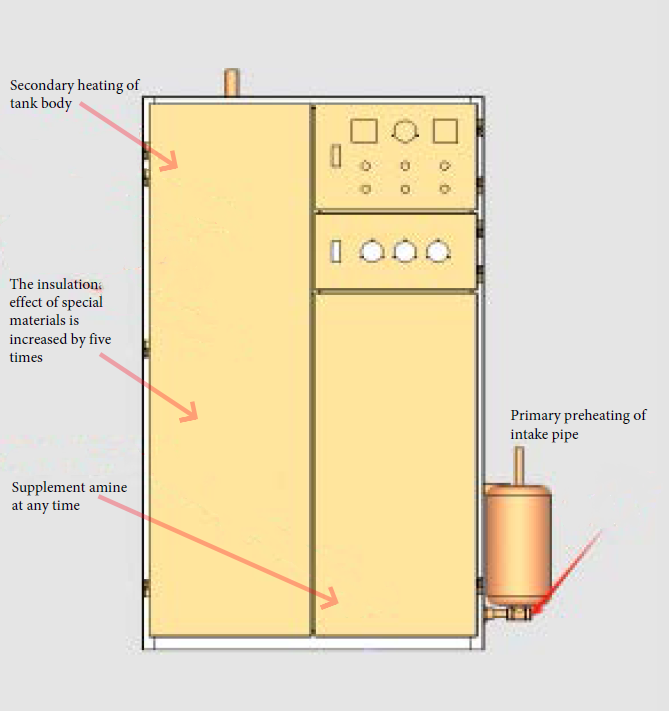

The latest generator technology is controlled by a PLC program. Process parameters can be set on the touch screen, and the workflow display and fault diagnosis display are available, enabling full automatic operation and control of imported electric proportional valves for pressure control.

The in take air uses eddy- current technology for physical heating. The atomization ratio reaches 98%, and the outlet air temperature remains constant at 80°C, allowing the chemical components to fully volatilize. The heat- preservation performance inside the atomization tube is improved by 400%.

It can achieve different pressure increasing curves according to various process requirements.

It features dual- temperature- controlled explosion- proof heating and gasification, with good safety performance.

It is equipped with an internal thermal energy storage device, offering high heating efficiency, good gasification effects, and low amine consumption. It is not affected by environmental temperature differences, ensuring stable production efficiency

The DR series one- to- two triethylamine gas generators are patented products of our company. They can supply two cold- box core shooters to produce sand cores of different specifications simultaneously or alternately without mutual interference. The parameters of the two sets can be independently set and modified.