- support@domain.tld

- +86051983732179

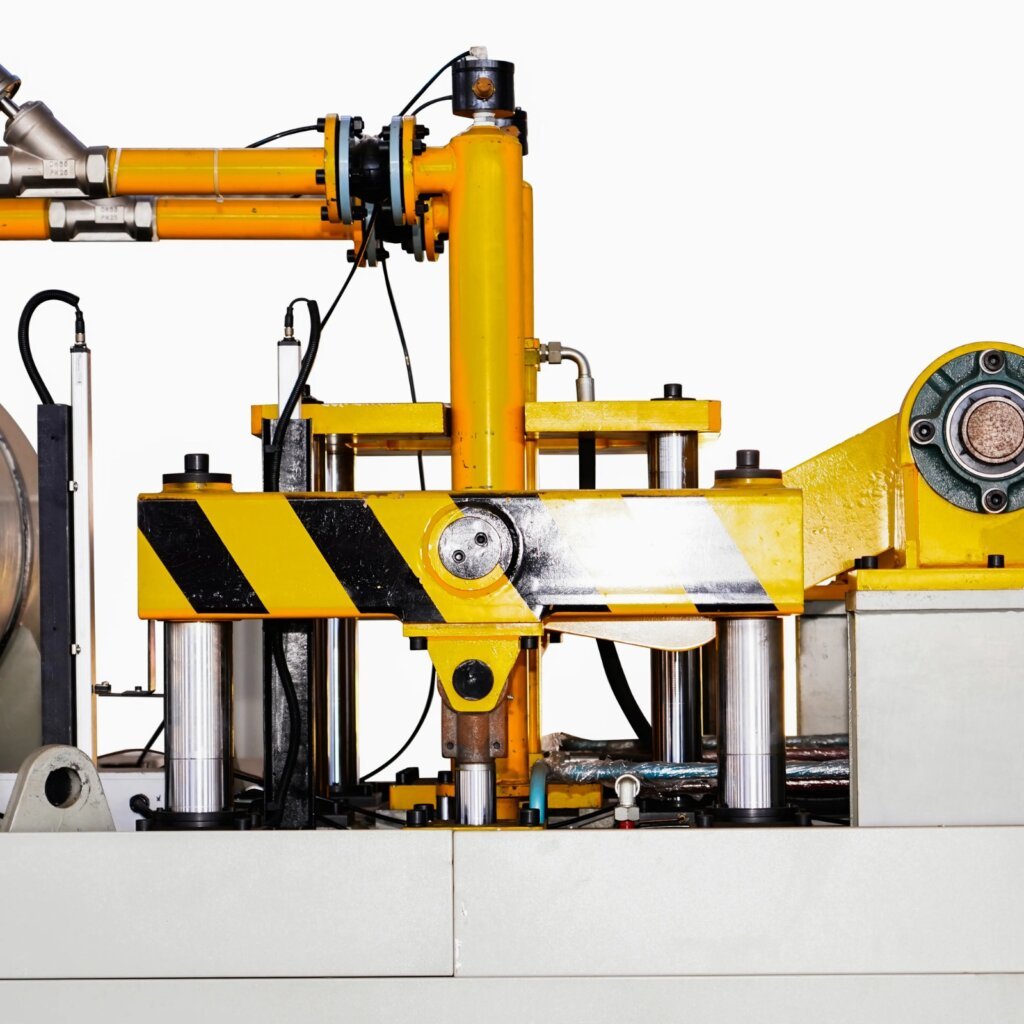

Warm core box technology is one of the core technologies in modern, large-scale casting production that pursues the best balance point of “quality, efficiency, and cost”. It is particularly suitable for fields such as automotive engines that have strict requirements for the quality of the inner cavity of castings. Although the initial investment is relatively high, the high production efficiency, excellent casting quality, and good working environment it brings make it occupy an irreplaceable position in the high end casting industry. With the increasing environmental requirements and the development of lightweight mold technology, the application prospects of the warm core box process are still broad.

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

Typical temperature range: 150 ° C-250 ° C. It has lower energy consumption than the heat core box

The curing time usually ranges from tens of seconds to a few minutes. Suitable for large-scale, assembly line production

High strength: When taking the core, it has high strength, which is convenient for subsequent handling and assembly

Controllable gas generation: By precisely controlling the amount of resin and curing degree, the gas generation is relatively stable

High dimensional accuracy: Due to solidification in a preheated and rigid core box, the deformation of the sand core is small, and very accurate casting cavity dimensions and surface smoothness can be obtained

Improvement of working environment: Compared to some cold core box processes with strong odors (such as furan resin), the gas in warm core boxes (especially triethylamine or SO ₂ processes) has less irritating odors in the workshop under effective ventilation.

Low energy consumption: Compared to the hot core box, the heating energy consumption can be reduced by 30%-50%.

We can produce medium to large-sized sand cores ranging from hundreds of grams to hundreds of kilograms