- support@domain.tld

- +86051983732179

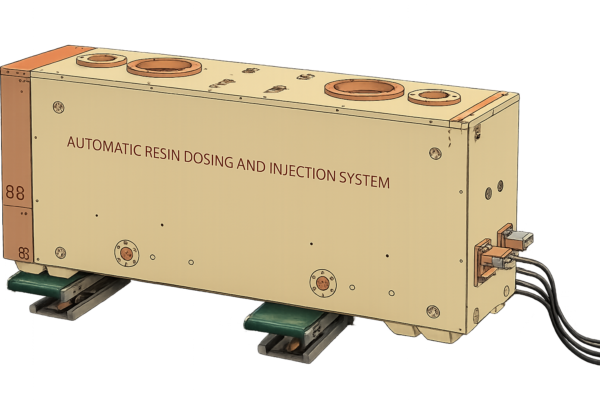

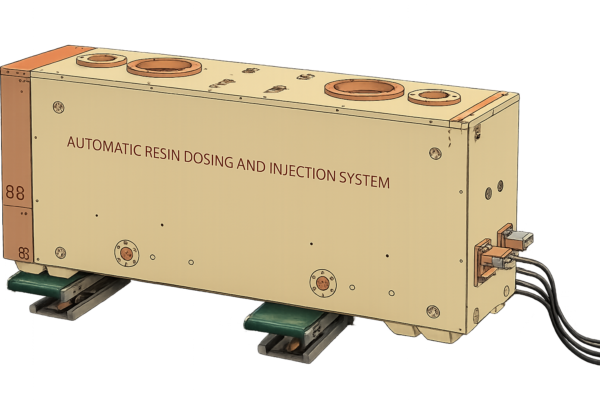

DRATEC resin quantitative filling system is a highly efficient and precise industrial equipment. It is a

device that can ensure the precise control of the filling amount of resin materials through continuous

monitoring and adjustment of the filling process while being linked with the sand mixer, thereby

improving production efficiency and product quality. During the production process, the resin

materials in the storage device are sent to the quantitative device for accurate measurement. Then,

the filling device transports the quantified resin to the target location. The control system

continuously monitors and adjusts throughout the process to ensure the accuracy and stability of the

filling amount and achieve real-time linkage with the sand mixer

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

Firstly, it can significantly improve production efficiency. The automated filling process reduces the time and cost of manual operation.

Secondly, precise control of the resin filling amount helps to improve product quality and production consistency.

In addition, the resin quantitative filling system is also easy to maintain and upgrade, and can

adapt to changes in different production requirements

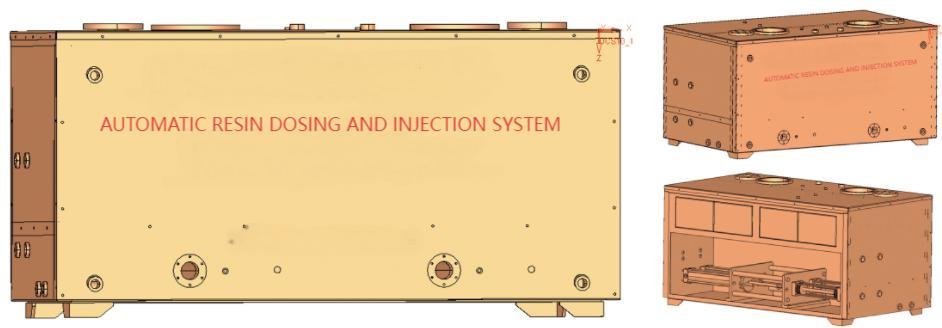

It is equipped with two sets for storing the resin materials to be filled. The device is designed with sufficient capacity to ensure the resin supply during the continuous production process. It is equipped with two resin constant-temperature radiation insulation boxes and an automatic temperature control device, which can effectively ensure that the resin in the storage box is heated at a constant temperature when the ambient temperature is too low, avoiding the error in resin quantification or injection amount caused by the decrease in the fluidity of the resin material due to low temperature.

It consists of two sets of volume- based quantitative methods. Quantification is achieved through a hydraulically- driven piston cylinder. It can automatically adjust the separate quantitative values of the two resins according to the parameters preset in the control system to meet production requirements

After the two quantified resin materials are respectively quantified by the hydraulically- driven piston cylinders, the separate quantitative filling of the two resins is achieved through components such as pipes and nozzles. The design of this device ensures that the resin can be evenly and stably transported to the designated location.

The displacement sensor monitors parameters such as the filling amount and flow rate of the resin in real- time. The controller adjusts the working state of the filling device according to these parameters to ensure the precise control of the filling amount. The actuator is responsible for executing the instructions of the controller, such as starting or stopping the operation of the hydraulic pump