- support@domain.tld

- +86051983732179

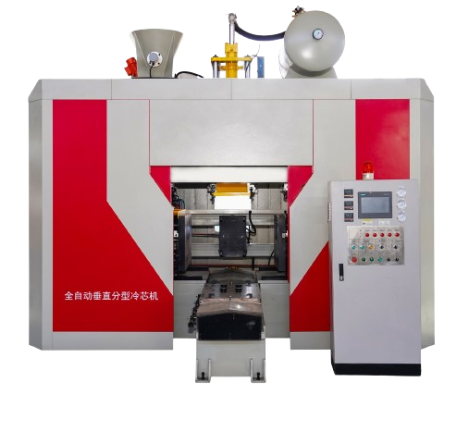

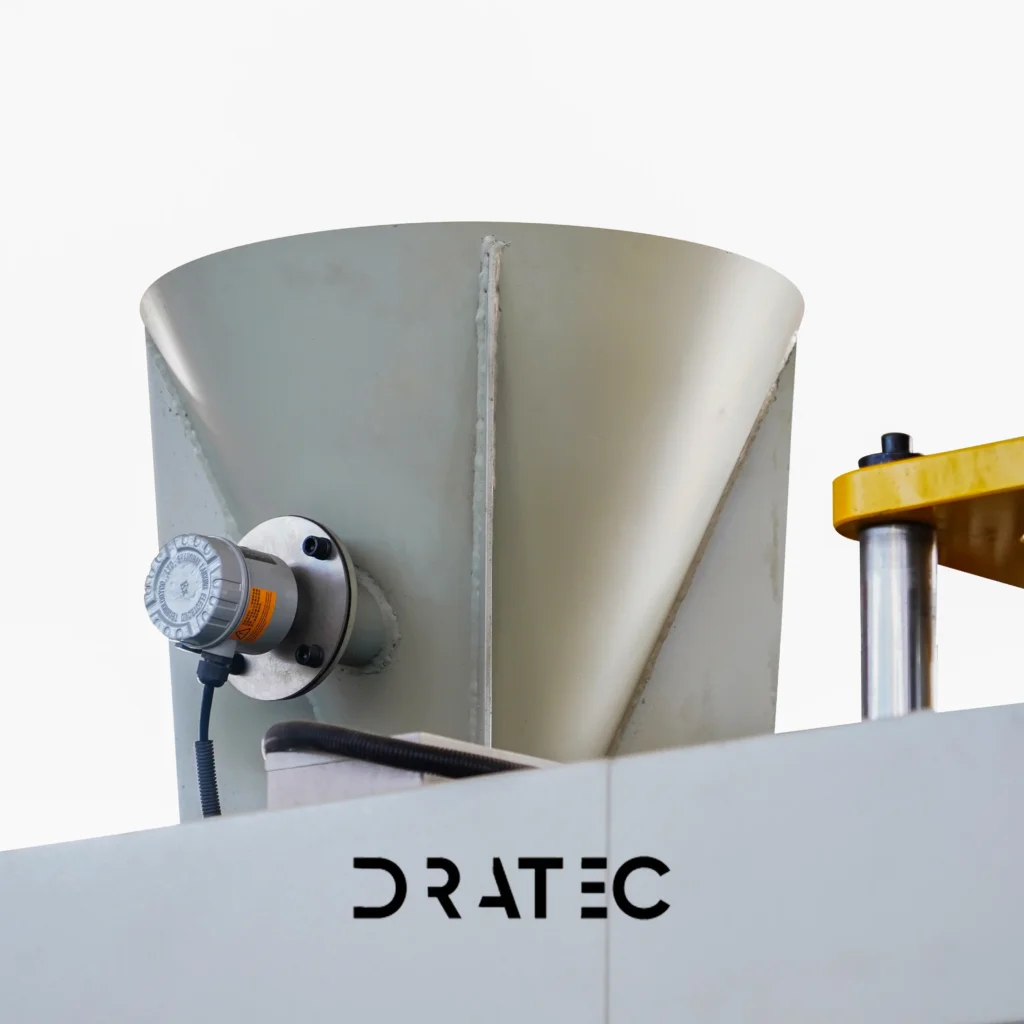

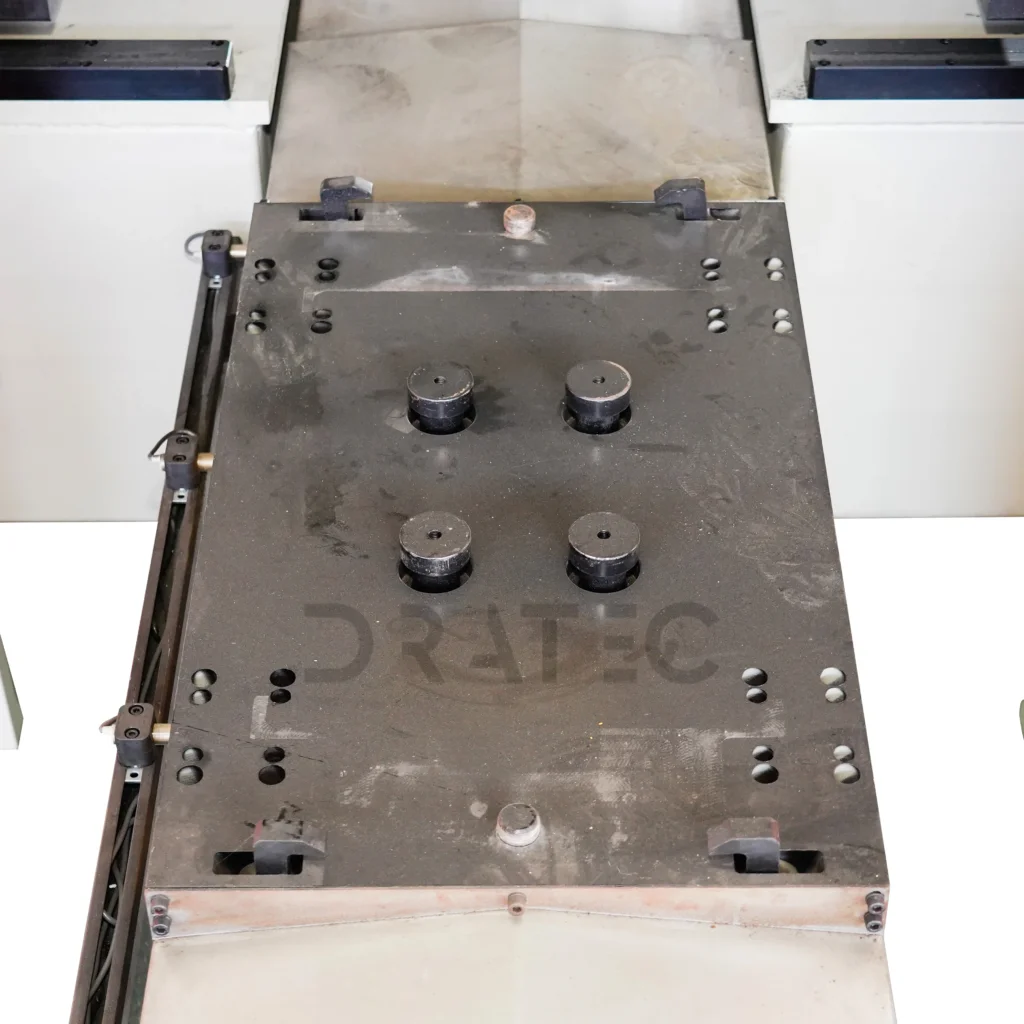

DRATEC Cold Box Core Shooting Machine ( CO₂/Sodium Silicate Process), also called Cold Box Shell Core Making Machine ,Cold Box Core Shooter Machine.. Our advanced core shooter machine is engineered for high-speed production of sand cores and molds using CO₂ or amine gas curing. It delivers superior performance, unmatched precision, and exceptional operational ease.

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

| Model | Z9405L-20A | Z9406L-30A | Z9407L-40A | Z9408L-40A | Z9409L-60A | Z9410L-70A | Z9412L-80A |

|---|---|---|---|---|---|---|---|

| Maximum core box size (mm) | 500×400×400 | 600×500×400 | 700×500×450 | 800×600×450 | 900×700×500 | 1000×800×500 | 1200×900×600 |

| Effective sand shooting area | 400×200 | 500×200 | 600×250 | 700×300 | 750×350 | 800×350 | 900×400 |

| Mould closing/opening distance (mm) | 300–800 | 300–800 | 400–900 | 450–1200 | 450–1200 | 500–1200 | 500–1200 |

| Maximum sand shot amount (kg) | 20 | 30 | 50 | 50 | 80 | 80 | 100 |

| Single station cycle time (s) | 25 | 30 | 30 | 35 | 35 | 40 | 40 |

| Drive mode | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics |

| Coring method | Workbench removal | Workbench removal | Workbench removal | Workbench removal/tooling | Workbench removal/tooling | Workbench removal/tooling | Workbench removal/tooling |

Ideal for CO₂-sodium silicate and cold box processes, achieving rapid curing for maximum output with minimal gas consumption and low operational cost

User-friendly LCD interface allows for easy parameter setup, real-time monitoring, and fault diagnosis. Choose from manual, automatic, or jog modes for flexible operation

Vibration-assisted high-pressure shooting ensures cores with excellent strength, precise dimensions, and smooth surfaces—guaranteeing zero waste and minimal sand residue.

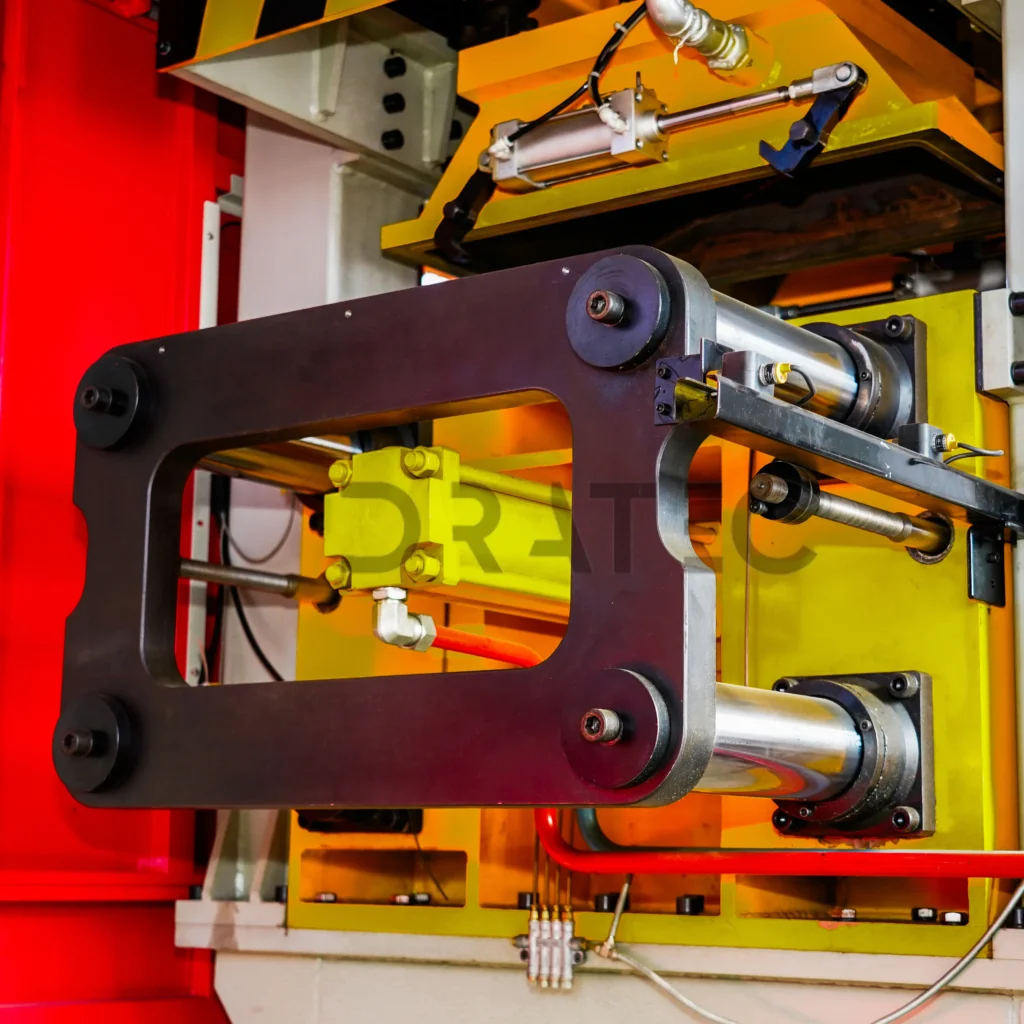

High-precision guided movement and automatic curing cycles ensure consistent quality. With hardened chrome-plated guide rails and automatic lubrication, the machine is designed for reliable, long-term performance.

The unique top-eject system keeps cores in the lower mold for easy, out-of-machine removal—no extra core-catching equipment needed.

Fully sealed doors and enclosures contain the process, providing a cleaner and safer workshop environment.

Available in vertical or horizontal parting styles with 2 to 6 mold-opening options to meet your specific production needs.