- support@domain.tld

- +86051983732179

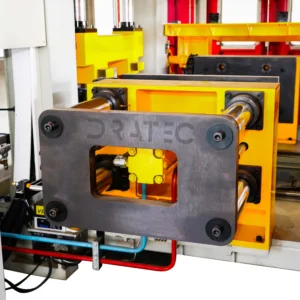

DRATEC Cold Box Horizontal Parting Core Shooting Machine, also called Cold Box Shell Core Making Machine ,Cold Box Core Machine…, refers to adopting a core box at normal temperature and using amine(TEA, DMA, etc.) as a catalyst to cure the phenolic resin-coated sand. Both the vertical parting and horizontal parting can be used. This processing represents the mainstream of today’s sand core-making technology. It has been widely used in foundry workshops for automobiles, spare parts, engines, valves, and electrical accessories in these industries.

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

| Model | ZH860L-30A | ZH1080L-40A | ZH1210L-50A | ZH1412L-60A | ZH1814L-80A | ZH2215L-150A | ZH2510L-100A |

|---|---|---|---|---|---|---|---|

| Maximum core box size (mm) | 800×600 | 1000×800 | 1200×1000 | 1400×1200 | 1800×1400 | 2200×1500 | 2500×1000 |

| Mould closing/opening distance (mm) | 350–850 | 350–850 | 400–900 | 450–950 | 500–1000 | 500–1000 | 450–950 |

| Maximum sand shot amount (kg) | 30 | 40 | 50 | 70 (Customizable) | 100 (Customizable) | 150 (Customizable) | 150 (Customizable) |

| Single station cycle time (s) | 20/30 | 25/30 | 30 | 35 | 40 | 40 | 45 |

| Number of molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds | 2–5 molds |

| Drive mode | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics | Servo Hydraulics/Frequency conversion motor | Servo Hydraulics/Frequency conversion motor | Servo Hydraulics/Frequency conversion motor |

| Coring method | Workbench removal | Workbench removal | Workbench removal | Workbench removal | Workbench removal | Workbench removal | Workbench removal |

Designed for cold box resin sand cured rapidly with TEA or CO₂, this system produces high-quality cores and molds with high efficiency, low cost, and minimal emissions.

PLC-controlled with an intuitive LCD interface, it supports manual/automatic/jog modes. Patented vibration-assisted sand shooting ensures precise, strong cores with smooth surfaces, zero scrap, and minimal waste.

Designed for cold box resin sand cured rapidly with TEA or CO₂, this system produces high-quality cores and molds with high efficiency, low cost, and minimal emissions.

A top ejector keeps cores in the lower mold, which moves out for extraction—no core-catching cart needed. Durable chrome-plated guide rails with auto-lubrication and cleaning extend service life

A movable work table simplifies mold setup and core removal. Fully sealed doors and screens ensure a clean workspace. The integrated DR-series TEA generator minimizes amine use without secondary blowing.

Available in horizontal parting models with 2–6 openings and optional side core-pulling. Drive options include variable frequency, pneumatic, servo hydraulic, or hybrid systems. Accessories include molds, quick-change plates, and sand feeders.