- support@domain.tld

- +86051983732179

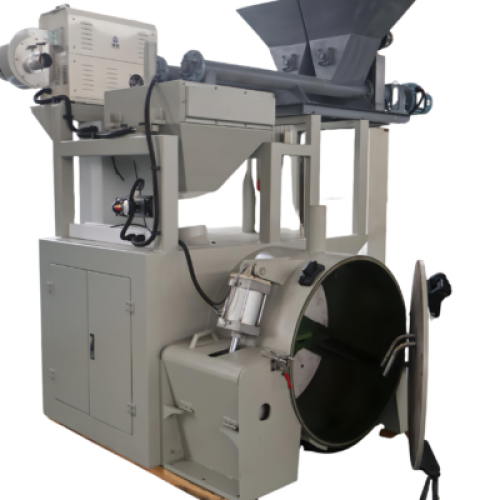

DRATEC sand mixers has strong adaptability and comprehensive application and is widely used to

mix moulding sand in foundry workshops. It can mix single sand and dry moulding sand, self

hardening sand, surface sand, and core sand. It’s also suitable for mixing various powder and granular

materials in glass, ceramics, and refractory materials.

Casting Process: (e.g., Sand Casting, Investment Casting, Die Casting, etc.)

Part Dimensions: (Length x Width x Height, or a reference drawing)

Max. Part Weight: (The weight of a single casting)

Annual Production Volume: (The total number of parts produced per year)

With your input, we can engineer a machine that perfectly fits your operational needs.

The vertical drum sand mixer is driven and controlled by a vertical variable- frequency motor and a reducer, with its efficiency increased by 100%. It has excellent sand- mixing effects. Compared with the traditional horizontal bowl- type sand mixer, it reduces the resin addition by approximately 15%. The weight range of each sand- mixing operation can be controlled according to the electronic weighing method or the time-flow method, and the error can be controlled within 0.2- 0.5 kg. It is also in real-time linkage with the resin dosing and injection system by adjusting the numerical parameters of the control system. The contact area inside the sand mixer is coated with anti- sticking paint for easy cleaning of the sand-mixing chamber.

During each sand-mixing operation of the sand-mixing mechanism, the pre-measured raw sand is added to the sand- mixing drum by the raw sand dosing system. Under the uniform agitation of the sand- mixing blades, the resin dosing and injection system injects the resin (two components) according to the required parameters. When the sand- mixing is completed, the sand discharge door of the sand- mixing drum opens, and the mixed core sand is added to the hopper of the cold- box core machine below the sand mixer under the action of gravity or is sent to the hopper of the cold- box core machine in need by the equipped core- sand transfer vehicle.

The sand-mixing mechanism is mainly composed of a sand- mixing drum, sand- mixing blades, wear- resistant plates, a drive motor, and a reducer

The control system automatically controls the sand mixer through a PLC, AC contactors, command switches, etc

The sand dosing hopper is located at the upper part of the sand mixer. It is connected to the sand silo through a butterfly valve upwards and communicates with the sand- mixing drum through a butterfly valve downwards. The raw sand in the sand dosing hopper is heated by the hot- air circulation system (sand heating is carried out when the external temperature is low), and the heating temperature can be adjusted on the temperature control system